Field Engineering Group Excels with Enhanced 3D Laser Scanning Capabilities

October 2, 2018

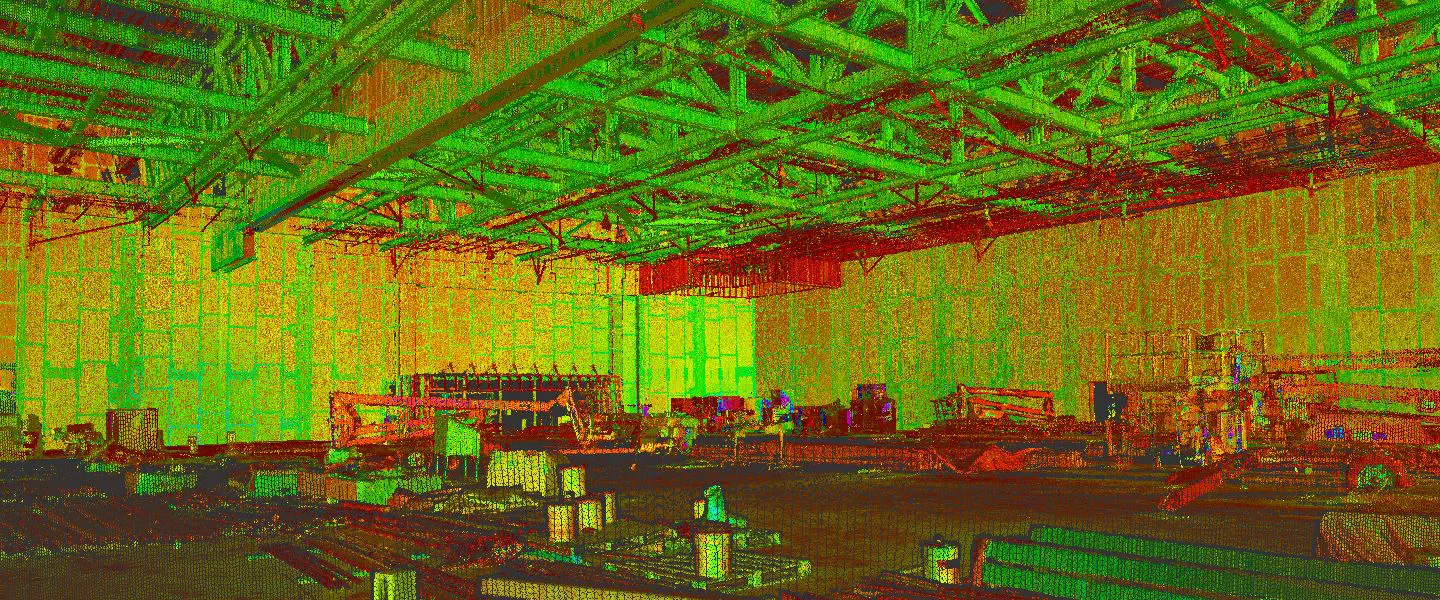

They say you can’t teach an old dog new tricks. While that might be true, Clark’s Field Engineering Group has found a way to use old technology with new tricks to add value on complex projects. Through the utilization of 3D laser scanning technology, high definition scanners, and new Virtual Design and Construction (VDC) software, the Field Engineering Group has the capability to provide accurate point clouds for as-built drawings, 3D visualization workflows, BIM CAD models, and digital scene reconstruction.

While 3D laser scanning has been utilized in the industry for the past 15 years, new technology has changed the game. High-definition scanners capture dimensions and spatial relationships by sending out laser beams which reflect off objects and return to the scanner’s sensors. The system creates coordinates for each point and consolidates the data into large point clouds. Combining point clouds and 360-degree photos of a scan location, modeling software aligns the scan and photos with color values to create a 3D color point cloud.

12 elevator shafts at the Miami Beach Convention Center

The Field Engineering Group's scanning initiatives, led by Dieter Agate, Greg Galasso, and Tim Edwards, apply in-house 3D scanning and modeling capabilities to mitigate as-built drawing inaccuracies for renovation and retrofit projects, which often rely on decades old drawings and building plans. Outdated or incomplete plans can result in inaccurate design drawings, leading to costly delays and setbacks. The Field Engineering Group is using enhanced 3D scanning to develop accurate 3D models of existing conditions, saving projects time and money.

The point-cloud-based as-built models improve designs by analyzing clashes between newly-designed elements and existing conditions, and by evaluating alternative designs prior to construction. The high accuracy of the scans minimizes waste and changes in the field by providing exact measurements for demolition and removal of components, as well as for prefabricated materials.

Applications and deliverable products include but are not limited to, existing conditions/pre-construction surveys, topography and quantity surveys, S.O.E. asbuilts/monitoring, pursuit presentations, etc.

At the Miami Beach Convention Center Renovation and Expansion, Clark’s Field Engineering team utilized 3D laser scanning to map 12 elevator shafts, along with the 50-foothigh perimeter walls of the 60,000-square-foot ballroom. Dieter and Tim collaborated with Clark’s VDC team to use a Leica BLK360 laser scanner on the project. Using conventional survey methods, gathering accurate data for the elevators and ballroom would have taken at least eight days. Collecting more than 225 million data points, the laser scanning process took just 12 hours and the data was used to generate valuable 3D models for construction planning and coordination.

“Thanks to the 3D laser scanning, we were able to start work in the elevator shafts as soon as the concrete walls were completed,” stated Rick Yezzi, Project Executive at the Miami Beach Convention Center project. “This process was a huge help for keeping our elevator installation on schedule because it allowed us to confirm dimensions and correct any issues before our trade partners mobilized in the shafts.”

Working together, Clark’s Field Engineering Group and VDC team are developing in-house, cost-effective capabilities and processes to streamline data collection and workflows to provide better information to project teams faster and more efficiently. Currently, Clark has 5 laser scanners with one, a Leica P20, being able to generate 1-million coordinated points per second.

In addition to the Miami Beach Convention Center, the Field Engineering Group’s enhanced 3D laser scanning and VDC practices have already been applied to projects including the International Spy Museum, Midtown Center, 1101 16th Street, and the CSX Virginia Avenue Tunnel. The Field Engineering Group, along with collaboration with the V.D.C. team, and the acquisition of new scanners and software expect high definition 3D laser scanning to become an invaluable resource for our project teams.